joey.lisano

New member

Why the GD chassis needs an X-brace

Previously

I talked about bushings in Bushing Selection: Rubber vs. Polyurethane. There's a lot of them, and I don't even have them all yet, but they're very important for the dynamic alignment of the car.

From the soft stock rubber bushings.......... To firmer bushings

*Note: that's not an STI's suspension. It's just a generic suspension animation that I found, but I think it helps visualize the concept.

*Note: that's not an STI's suspension. It's just a generic suspension animation that I found, but I think it helps visualize the concept.

Cornering forces and chassis flex

Take another look at the first animation with the stock bushings, and imagine the STI's rear suspension. For a cornering force pointing to the right, the lateral links want to go to the right, and the strut tops want to go to the left. For the right wheel, which is not shown, the lateral links again move right while the strut tops move left because the cornering force points in the same direction for both tires. The lateral links connect to the rear subframe, which connects to the chassis, and the strut tops connect to the chassis. Because the rear subframe pushes one way and the strut tops push the other, this creates chassis flex.

A four bar linkage as a model

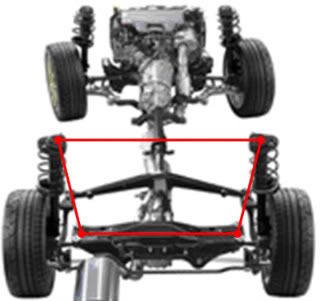

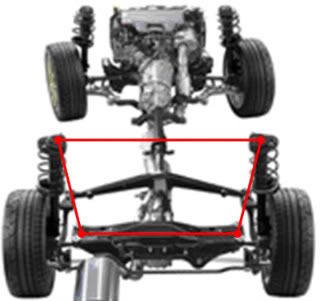

Here is a picture of the GD's rear suspension. I put dots at the four mounts to the chassis and connected the dots.

You see that the lines create a trapezoid. If we assume that the dots are weak connections and the lines are rigid links, the system can be modeled as a four bar linkage. The animation below shows how a four bar linkage would react to a leftward force from the strut tops. The lateral link force is not show, but it would be on the bottom and pointing to the right, which helps to further deform the chassis.

Is this model valid? How do we know the chassis is flexing? From my personal experience, I got the try the Litespeed rear chassis bridge on my stock suspension. That means stock tires, stock alignment, stock sway bars, stock springs, stock bushings, etc. Moreover, I was driving on the street, not a track where I could go really fast. The difference that the Litespeed brace made was phenomenal. Because it made such a big difference in feel, it proves that there is appreciable chassis flex, even on a completely stock car. I'd rank the Litespeed rear chassis bridge up there with the ALK in terms of overall improvement. It's below the sway bar territory, but above some/most of the bushings. It costs less than a rear strut bar, and I definitely recommend getting on instead of a strut brace. Hopefully, you will understand why.

In addition, I think the X-brace's video is another good example. In the video, the X-brace is connected to the rear strut tops, but it is unbolted from the bottom. Thus, what you are seeing is the top's movement relative to the bottom. It may not seem like a ton of motion, but that's exactly what firmer bushings do - prevent unwanted motion and maintain a better dynamic alignment.

Triangulation

How do you stop the chassis from flexing? Brace it - but not just any kind of brace, we need to triangulate. Roll cages, aftermarket front subframes, fender cowl braces, etc. Triangles are good because they turn the linkage into a rigid structure.

Of course, that animation only shows half the traditional X-brace. Also, the X-brace can be made of cables. While a wire cannot be compressed, the other diagonal wire will be in tension and resist the movement. What's the difference between the X-brace and Litespeed rear chassis bridge? The X-brace has <0 degrees of freedom and is statically indeterminant, while the Litespeed brace has 0 degrees of freedom. They're both rigid configurations; therefore, the difference is null. This is why Eric noble, the designer of the X-brace, said you can make the brace with cables. If there is a difference, I'd say it's that the Litespeed rear chassis bridge is easier and faster to install. Also, it weighs about 7 lb less while still providing ample strength due to the custom manufactured cables. (Check out Gruebler's equation for more info on degrees of freedom.)

Why don't the black LATCH bars work? Simple, they don't really triangulate. They are vertical, which is too similar to the right and left links in the suspension's trapezoid shape. They may look cool, and you might think any kind of bracing must do something, but they were made to hold the baby seat. They also hold the Spec C water tank if you want an aquarium in your trunk.

What about an X-brace for the front subframe and struts? There is a similar trapezoid on the front suspension, too. While that's true, the firewall is very close to the front struts; consequently, it acts like a pseudo-X-brace. Moreover, fitting a front X-brace is geometrically impossible with the transmission in the way. Luckily, there are front subframe braces and front strut bars that try to help out by bracing the surrounding areas.

Previously

I talked about bushings in Bushing Selection: Rubber vs. Polyurethane. There's a lot of them, and I don't even have them all yet, but they're very important for the dynamic alignment of the car.

From the soft stock rubber bushings.......... To firmer bushings

Cornering forces and chassis flex

Take another look at the first animation with the stock bushings, and imagine the STI's rear suspension. For a cornering force pointing to the right, the lateral links want to go to the right, and the strut tops want to go to the left. For the right wheel, which is not shown, the lateral links again move right while the strut tops move left because the cornering force points in the same direction for both tires. The lateral links connect to the rear subframe, which connects to the chassis, and the strut tops connect to the chassis. Because the rear subframe pushes one way and the strut tops push the other, this creates chassis flex.

A four bar linkage as a model

Here is a picture of the GD's rear suspension. I put dots at the four mounts to the chassis and connected the dots.

You see that the lines create a trapezoid. If we assume that the dots are weak connections and the lines are rigid links, the system can be modeled as a four bar linkage. The animation below shows how a four bar linkage would react to a leftward force from the strut tops. The lateral link force is not show, but it would be on the bottom and pointing to the right, which helps to further deform the chassis.

Is this model valid? How do we know the chassis is flexing? From my personal experience, I got the try the Litespeed rear chassis bridge on my stock suspension. That means stock tires, stock alignment, stock sway bars, stock springs, stock bushings, etc. Moreover, I was driving on the street, not a track where I could go really fast. The difference that the Litespeed brace made was phenomenal. Because it made such a big difference in feel, it proves that there is appreciable chassis flex, even on a completely stock car. I'd rank the Litespeed rear chassis bridge up there with the ALK in terms of overall improvement. It's below the sway bar territory, but above some/most of the bushings. It costs less than a rear strut bar, and I definitely recommend getting on instead of a strut brace. Hopefully, you will understand why.

In addition, I think the X-brace's video is another good example. In the video, the X-brace is connected to the rear strut tops, but it is unbolted from the bottom. Thus, what you are seeing is the top's movement relative to the bottom. It may not seem like a ton of motion, but that's exactly what firmer bushings do - prevent unwanted motion and maintain a better dynamic alignment.

Triangulation

How do you stop the chassis from flexing? Brace it - but not just any kind of brace, we need to triangulate. Roll cages, aftermarket front subframes, fender cowl braces, etc. Triangles are good because they turn the linkage into a rigid structure.

Of course, that animation only shows half the traditional X-brace. Also, the X-brace can be made of cables. While a wire cannot be compressed, the other diagonal wire will be in tension and resist the movement. What's the difference between the X-brace and Litespeed rear chassis bridge? The X-brace has <0 degrees of freedom and is statically indeterminant, while the Litespeed brace has 0 degrees of freedom. They're both rigid configurations; therefore, the difference is null. This is why Eric noble, the designer of the X-brace, said you can make the brace with cables. If there is a difference, I'd say it's that the Litespeed rear chassis bridge is easier and faster to install. Also, it weighs about 7 lb less while still providing ample strength due to the custom manufactured cables. (Check out Gruebler's equation for more info on degrees of freedom.)

Why don't the black LATCH bars work? Simple, they don't really triangulate. They are vertical, which is too similar to the right and left links in the suspension's trapezoid shape. They may look cool, and you might think any kind of bracing must do something, but they were made to hold the baby seat. They also hold the Spec C water tank if you want an aquarium in your trunk.

What about an X-brace for the front subframe and struts? There is a similar trapezoid on the front suspension, too. While that's true, the firewall is very close to the front struts; consequently, it acts like a pseudo-X-brace. Moreover, fitting a front X-brace is geometrically impossible with the transmission in the way. Luckily, there are front subframe braces and front strut bars that try to help out by bracing the surrounding areas.

Last edited: