You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2013 Satin White Pearl STi Limited

- Thread starter Boogieman98

- Start date

Sent from my iPhone using Tapatalk

Looks great! What AOS do you have installed?

I have the IAG Street version. Can be converted to the race easily

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I have the IAG Street version. Can be converted to the race easily

I've been trying to figure out what the difference is between the two versions. I now see that there is some kind of conversion kit and the street AOS is actually more expensive than the "competition" AOS. Hmmm...

Here was the build list for the current build. Some of the parts were carried over from previous builds

Block Built by Watts Shop ( Guy who builds the T1 GTR engines )

CP Forged Pistons with Moly Coating on Skirts

Golden Eagle Ductile Iron Pinned Sleeves

Copper O-ringed

Balanced & Blueprinted

Callies Ultra Enforcer Rods

OEM Nitrided Crankshaft

King Bearings

ARP Head Studs (STD)

BC Stage 2 272 Camshafts

1mm Oversized Ferra Competition Plus Stainless Intake Valves

1mm Oversized Ferra Competition Plus Stainless Exhaust Valves

BC Springs and Titanium Retainers

Factory Shimless Buckets

Full Bowl Port and Match with Three Angle Valve Job

Killer Bee Oil Pan and Pick up

ID 1300 CC Injectors

Walbro 525 Hellcat Pump

Fuelab Black- In-Line Fuel Filter

Aeromotive FPR @ 60psi Base Pressure

Cobb Flex Fuel Kit

IAG Fuel Rails

Visconti Fuel Basket Upgrade

Grimmspeed EBCS

MAPerformance equal length header

Grimmspeed Up-pipe

TiAL 44mm EWG

SPT Cat back exhast

Catless Downpipe

Fluidampr Crank Pulley

GrimmSpeed Top Mount Intercooler

COBB XLE BPV

FP Black JB Turbo

IAG Air Oil Separator

Block Built by Watts Shop ( Guy who builds the T1 GTR engines )

CP Forged Pistons with Moly Coating on Skirts

Golden Eagle Ductile Iron Pinned Sleeves

Copper O-ringed

Balanced & Blueprinted

Callies Ultra Enforcer Rods

OEM Nitrided Crankshaft

King Bearings

ARP Head Studs (STD)

BC Stage 2 272 Camshafts

1mm Oversized Ferra Competition Plus Stainless Intake Valves

1mm Oversized Ferra Competition Plus Stainless Exhaust Valves

BC Springs and Titanium Retainers

Factory Shimless Buckets

Full Bowl Port and Match with Three Angle Valve Job

Killer Bee Oil Pan and Pick up

ID 1300 CC Injectors

Walbro 525 Hellcat Pump

Fuelab Black- In-Line Fuel Filter

Aeromotive FPR @ 60psi Base Pressure

Cobb Flex Fuel Kit

IAG Fuel Rails

Visconti Fuel Basket Upgrade

Grimmspeed EBCS

MAPerformance equal length header

Grimmspeed Up-pipe

TiAL 44mm EWG

SPT Cat back exhast

Catless Downpipe

Fluidampr Crank Pulley

GrimmSpeed Top Mount Intercooler

COBB XLE BPV

FP Black JB Turbo

IAG Air Oil Separator

Something I desperately need is a Fuel Pump Controller that can handle the additional amps that the hellcat pump needs. I have upgraded to the iWire harness for the stock FPC to retain the 33% 66% and 100% cycles but I cannot find anything aftermarket that can do this. it is either 100% on or you have to retain the stock FPC

This whole thing has me kind of confused. How have other people configured everything to use the Hellcat pump? I know that's what you want to use, but why not use a different high capacity pump? Would a Walbro 460lph for example, not provide enough fuel for your build? Considering your power numbers and the injectors you have installed, I feel like the Hellcat pump might not be necessary.

For what it's worth, I have a Walbro 460, FIC 1650cc injectors and a Tomei Type-L FPR. I don't have them installed yet, but I am confident they will support my power goals just fine (which I think are about on par with your's).

For what it's worth, I have a Walbro 460, FIC 1650cc injectors and a Tomei Type-L FPR. I don't have them installed yet, but I am confident they will support my power goals just fine (which I think are about on par with your's).

I agree that the 525 is over kill and the 485 I had in there potentially would have worked fine at this level. The only concern was whether or not the 485 could hold pressure at the top end with the base pressure being at 60 psi. My plan at some point would be to change to ID2000, FP Black Zero and a front mount. ( I have an issue with buying car parts ) I have been unable to find anyone who has done the 525 stand alone and not running it at a 100% all the time. I was looking at the Aeromotive FPC but I would have to retune to use it since it bases everything off of the RPM's and not the typical 33,66 & 100.

Well another one bites the dust boys. Need some insight and your thoughts. [MENTION=1172]Alin[/MENTION], [MENTION=9]HolyCrapItsFast[/MENTION], [MENTION=662]Batmobile_Engage[/MENTION], [MENTION=652]Grinder34[/MENTION]

While doing a log for Calvin Dotson of Dotson tuning my car apparently melts a spark plug and burns a valve. How you wonder? Gather around boys and girls I have a story

I start getting very random low voltage code on the Cobb Flex Fuel sensor when I would start the car. And say I mean random I mean every 2 - 3 weeks. I reach out to Shawn at Kraken and he said that I would have to get a log over to Cobb and it may need to be replaced. I reach out to Cobb and they instructed me to log all the time to see if I could catch it and when I do to send it to them. I couldn't catch it because when you start the car the damn Accessport restarts. I asked the representative at Cobb if the Flex-Fuel sensor fails is it going to damage my car. He confidently assured me it would not. During all of this I replaced the stock fuel assembly with the Radium Fuel Hanger and stayed with the same 525 hellcat pump that was in that stock hanger. I asked Calvin to look at a log to ensure that everything still looked good. My email to him below

His response

While doing a log for Calvin Dotson of Dotson tuning my car apparently melts a spark plug and burns a valve. How you wonder? Gather around boys and girls I have a story

I start getting very random low voltage code on the Cobb Flex Fuel sensor when I would start the car. And say I mean random I mean every 2 - 3 weeks. I reach out to Shawn at Kraken and he said that I would have to get a log over to Cobb and it may need to be replaced. I reach out to Cobb and they instructed me to log all the time to see if I could catch it and when I do to send it to them. I couldn't catch it because when you start the car the damn Accessport restarts. I asked the representative at Cobb if the Flex-Fuel sensor fails is it going to damage my car. He confidently assured me it would not. During all of this I replaced the stock fuel assembly with the Radium Fuel Hanger and stayed with the same 525 hellcat pump that was in that stock hanger. I asked Calvin to look at a log to ensure that everything still looked good. My email to him below

On Sun, Feb 16, 2020 at 6:56 PM Richard Wegmann <rickwegmann@me.com> wrote:

Hey Calvin, I just finished installing the Radium Hanger and fuel line kit. I installed a new 525 hellcat pump that was the same as the one that was in there. I did not upgrade the pump because I am still running the same size hoses to fuel rails from the ethanol sensor. The attached log has some knock and I am wondering if I need to bring it by your shop or not. The ethanol sensor will throw a code saying that the voltage is low. It does it right when the car starts so I can't get a log of it. Let me know your thoughts.

On February 17, 2020 at 11:14 AM, Calvin Dotson <calvin@dotsontuning.com> wrote:

I took the car back out to test the new map he provided. During the log I go WOT and the exhaust note changes like a cylinder is missing but not code. I let out of the throttle and go WOT again and it just doesnt accelerate like normal. So I limp home and then right before I get home I get a misfire code cylinders 1 & 3. I send and email to Calvin with the logLog doesn't look too bad other than the knock. I have made a small adjustment where you are seeing knock. If this gets rid of it then no need to bring it in. The code for the flex-fuel sensor is probably going to be the COBB Flex-fuel Module we have seen a few of the earlier ones fail like that. If you keep getting that code then you will likely need to get it replaced by COBB.

From: Richard Wegmann <rickwegmann@me.com>

Date: 2/17/2020

To: Calvin Dotson <calvin@dotsontuning.com>

Subject: Re: Log

Loaded your new map and took her for a spin. No knock but misfires in 3 cylinders. Running like shit now and stumbling but still no knock

Date: 2/17/2020

To: Calvin Dotson <calvin@dotsontuning.com>

Subject: Re: Log

Loaded your new map and took her for a spin. No knock but misfires in 3 cylinders. Running like shit now and stumbling but still no knock

I call him and he states he sees where the sensor is failing and advises me to reach out to Cobb to get the sensor replaced. After some questions they respond

Aaron Foo (COBB) (COBB Support)

Feb 19, 9:36 AM CST

Hey Richard!

Looking over that datalog that you provided it does indeed look like a Flex Fuel harness failure.

Can you please also provide:

Billing/Shipping Address

Phone number

Aaron Foo (COBB) (COBB Support)Feb 19, 9:36 AM CST

Hey Richard!

Looking over that datalog that you provided it does indeed look like a Flex Fuel harness failure.Can you please also provide:Billing/Shipping AddressPhone number

I call this representative and ask if it could have hurt my motor. He states no that the sensor is limp mode so to speak and that once I install the new sensor all will be good. I receive the new sensor and get it installed and still the car runs like shit. So I reach out to Shawn at Kraken motorsports and he advises me to pull the spark plugs and see if one has fouled out. I pull the plugs and find one that is melted

I call Shawn and he advises me to bring the car to him. It takes him about a month to get back to me and states that the car not only melted that plug but burned a hole in one of the valves. SAY WHAT?!! I call Cobb and tell them exactly what had happened and they stated they would reach out to Calvin and Shawn. I then drive out to Kraken's shop to see the car and to speak with Shawn. While I am there Shawn is speaking with Cobb and then hands me the phone. The representative states that the sensor was not the cause of the burnt spark plug or valve and that it must have been a mechanical failure that caused this and they would not be doing anything to assist with the repair. Shawn with Kraken Motorsports tell me that it would cost $4k-$5k to pull the motor and repair the valves and heads and that he does not know of any mechanical failure that would have caused that but assured me it would not have damaged the short block.

I at this point am about to lose my shit so decide to go home cool off and email Cobb, Shawn with Kraken and Calvin with Dotson Tuning. Email below

From: Richard Wegmann <rickwegmann@me.com>

Date: 3/31/2020

To: support@cobbtuning.com,Calvin Dotson <calvin@dotsontuning.com>,Shawn Rizzo <shawn@kraken-motorsports.com>

Subject: Flex Fuel Kit Failure - Support Ticket #436803

It was explained to me today by a representative at Cobb that the attached Accesport Log dated 2-17-2020 originally sent to Calvin Dotson of Dotson tuning shows that the Cobb flex-fuel sensor although failing was not the cause of engine failure experienced during this log but in fact a mechanical failure not associated with that flex-fuel sensor whatsoever. I would like it explained to me how you arrived that it was a mechanical failure not caused by the sensor and what type of mechanical failure would cause this. The engine failure experienced is a melted spark plug & valves per Shawn at Kraken Motorsports who built and installed the motor. I have also attached the log that was sent on 2-16-2020 to Calvin Dotson which shows no signs of a failing sensor or a possible mechanical failure that occurred the very next day.

The representative responds

Matthew Bryant (COBB Support)

Apr 1, 11:18 AM CDT

Hey Rick,

My name is Matt Bryant. I'm the Customer Service Manager at COBB, and also the one that you spoke with yesterday evening.

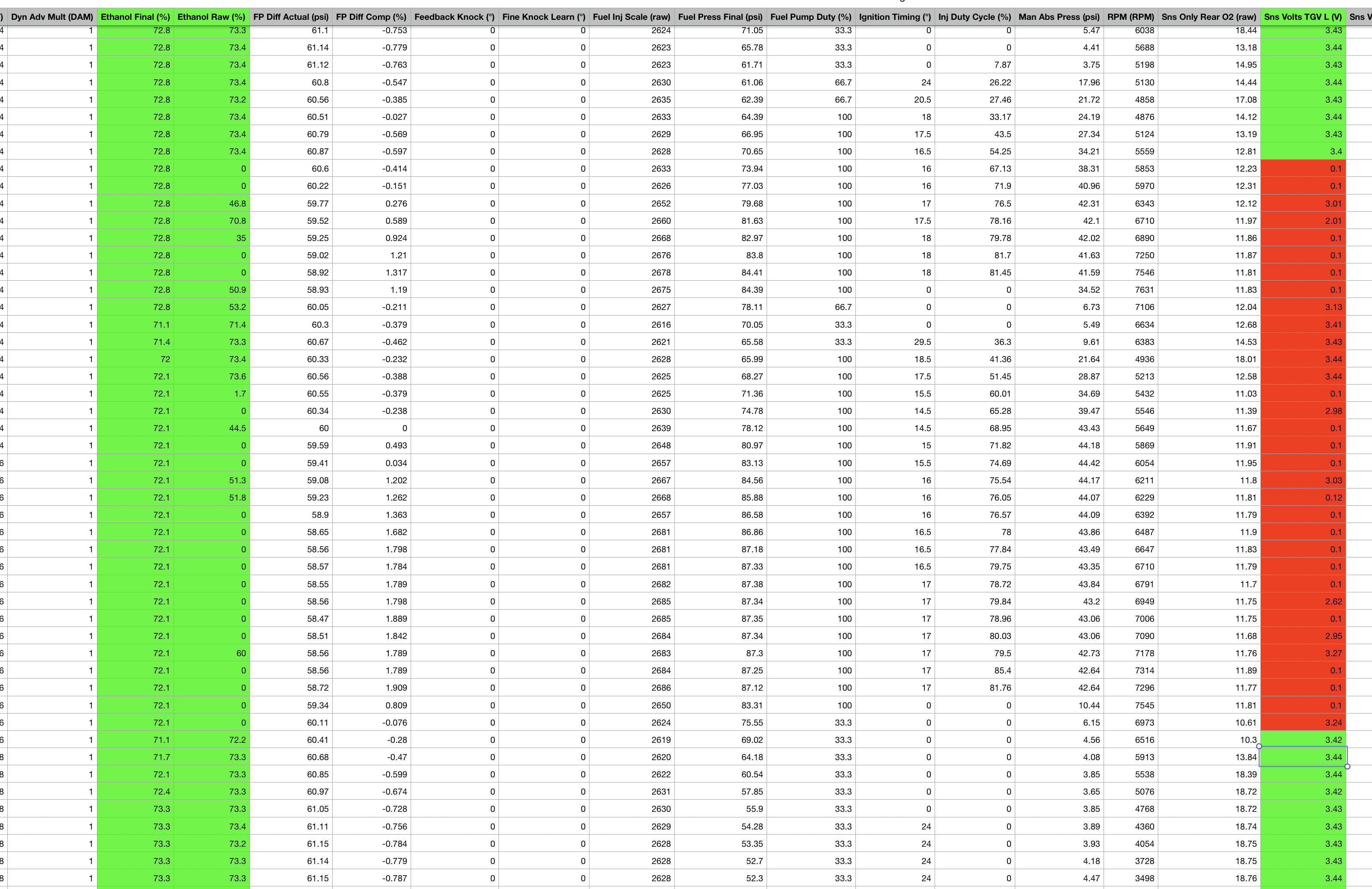

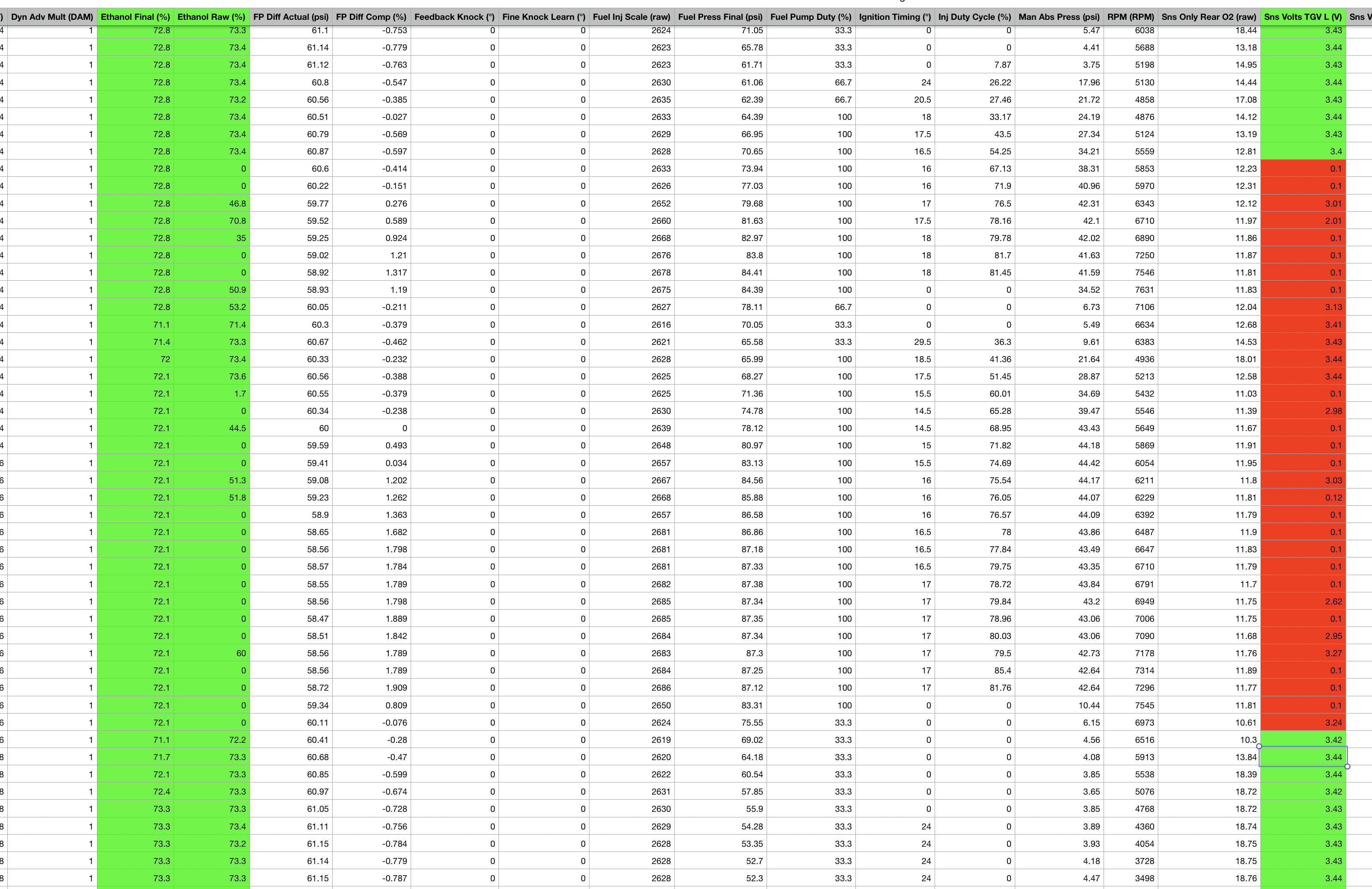

Below is a screenshot of the failure in the 2/3 gear pull you made and sent over to Aaron (COBB)/Calvin (Kraken) originally when we warrantied the flex fuel module.

?

?

As I mentioned on the phone yesterday, the module did indeed fail (indicated in red). You can see the voltage drop down to 0.1. However, due to the programming we've instituted, and the configuration of Calvin's tune, you can see that "Ethanol Final (%)" did not skew to any notable degree. It was consistent at around 72%-73%. Ethanol Final is what the calibration references for tuning purposes. Given that Ethanol Final did not skew, I'm confident in saying that the failure of the module did not contribute to your mechanical failure.

As for the datalogs you sent over:

As for what caused this failure, one can only guess. In my expert opinion, given the nature of this car (race car build, large turbo, built motor internals, nearly maxed fuel system, ~500wHP) I would suspect that something merely failed due to the high stress/heat that's associated with making that kind of power. Things break all the time on a totally stock car, not to mention especially when you're pushing them this hard as you are. Perhaps a spark plug failed, or the fuel pump had a hiccup, or who knows. Modern engines, not to mention heavily modified ones, are incredibly complicated beasts, so it's really tough to say, given the information I have on hand. I wish I could offer more direction, but Kraken and Calvin will be better resources for guiding you through this.

Apologies for not being able to take your call. I wanted to make sure that I had all the information at hand and had ample time to review your logs prior to chatting. If you'd like to speak later this afternoon, feel free to let me know, and I'll be happy to give you a call.

He obviously didn't look very well as the logs and the point of failure so I take the liberty to point it out in my response

From: Richard Wegmann <rickwegmann@me.com>

Date: 4/1/2020

To: COBB Support <support@cobbtuning.com>

Cc: Kraken Motorsports <calvin@dotsontuning.com>,Shawn <shawn@kraken-motorsports.com>

Subject: Re: [COBB Support] Re: Phone Call from: Richard Wegmann

Matthew,

Your observation pertaining to the ethanol content being consistent at around 72% - 73% during the 2 / 3 gear pull is incorrect. We are all in agreement that the actual ethanol content in the car for both logs was in the 72%-73% range. I want to explore the log provided on 2-17 when the engine failure occurred. That engine failure occurred during the cells 2275-2320 when sorted by column A Time (sec)

Cells 2275 ? 2283 shows Ethanol Final (%) 73.3 and Ethanol Raw (%) 73.3-73.6 which is normal when sensor working correctly as confirmed by 2-16 log.

Cell 2284 shows Ethanol Final (%) 73.3 and Ethanol Raw (%) drop to 50.2

Cell 2285 shows Ethanol Final (%) 73.3 and Ethanol Raw (%) drop to 0 when I let off the throttle and change gears

Cells 2286-2302 shows Ethanol Final (%) drop from the 73.3 to a low of 65.2 and Ethanol Raw (%) bounces around from 0 ? 73.3

Why is the ethanol final (%) dropping down to 65.2 when the last good reading was 73.3? Also, I don?t see ignition timing changing to compensate for this drop. This is where I hear the car sounds different and not accelerating as quickly and where I got the engine failure but didn?t know it.

I let off the throttle and then get back into it and then realize I have an issue.

Once I arrive home I send the log over to Calvin and then subsequently over to you guys

He responds

Matthew Bryant (COBB Support)

Apr 1, 6:56 PM CDT

Hey Rick,

Thanks for allowing me time to review your email/logs.

Your concern of Ethanol Final (%) variation, notable between shifts, could be contributed to by the ethanol sensor placement. For the most accurate/consistent performance, we've designed it to be installed within the pressurized system, pre-FPR (fuel pressure regulator). It may be worth confirming that you have it installed in that fashion. If you have it post-FPR, that would indicate why you see the fluctuations when shifting (low pump duty cycle (as you're off throttle), the return line would be nearly empty, the ethanol sensor would calculate erroneous values). Again, the fluctuations in the readout of Ethanol Final are minimal during steady states of throttle.

Even the Ethanol Final swing of 8.1% (65.2% vs. 73.3%) you mentioned would only account for about a small percentage change (single digit) in actual fueling, which is absolutely not enough to cause harm. For that matter, I didn't see any terribly concerning/red-flag lean conditions that would lead to a damaged spark plug or valve.

I still stand by my original statement that I don't believe the module is responsible for the reported engine damage.

Aaron Foo (COBB) (COBB Support)

Feb 19, 9:36 AM CST

Hey Richard!

Looking over that datalog that you provided it does indeed look like a Flex Fuel harness failure.

Can you please also provide:

Billing/Shipping Address

Phone number

Aaron Foo (COBB) (COBB Support)Feb 19, 9:36 AM CST

Hey Richard!

Looking over that datalog that you provided it does indeed look like a Flex Fuel harness failure.Can you please also provide:Billing/Shipping AddressPhone number

I call this representative and ask if it could have hurt my motor. He states no that the sensor is limp mode so to speak and that once I install the new sensor all will be good. I receive the new sensor and get it installed and still the car runs like shit. So I reach out to Shawn at Kraken motorsports and he advises me to pull the spark plugs and see if one has fouled out. I pull the plugs and find one that is melted

I call Shawn and he advises me to bring the car to him. It takes him about a month to get back to me and states that the car not only melted that plug but burned a hole in one of the valves. SAY WHAT?!! I call Cobb and tell them exactly what had happened and they stated they would reach out to Calvin and Shawn. I then drive out to Kraken's shop to see the car and to speak with Shawn. While I am there Shawn is speaking with Cobb and then hands me the phone. The representative states that the sensor was not the cause of the burnt spark plug or valve and that it must have been a mechanical failure that caused this and they would not be doing anything to assist with the repair. Shawn with Kraken Motorsports tell me that it would cost $4k-$5k to pull the motor and repair the valves and heads and that he does not know of any mechanical failure that would have caused that but assured me it would not have damaged the short block.

I at this point am about to lose my shit so decide to go home cool off and email Cobb, Shawn with Kraken and Calvin with Dotson Tuning. Email below

From: Richard Wegmann <rickwegmann@me.com>

Date: 3/31/2020

To: support@cobbtuning.com,Calvin Dotson <calvin@dotsontuning.com>,Shawn Rizzo <shawn@kraken-motorsports.com>

Subject: Flex Fuel Kit Failure - Support Ticket #436803

It was explained to me today by a representative at Cobb that the attached Accesport Log dated 2-17-2020 originally sent to Calvin Dotson of Dotson tuning shows that the Cobb flex-fuel sensor although failing was not the cause of engine failure experienced during this log but in fact a mechanical failure not associated with that flex-fuel sensor whatsoever. I would like it explained to me how you arrived that it was a mechanical failure not caused by the sensor and what type of mechanical failure would cause this. The engine failure experienced is a melted spark plug & valves per Shawn at Kraken Motorsports who built and installed the motor. I have also attached the log that was sent on 2-16-2020 to Calvin Dotson which shows no signs of a failing sensor or a possible mechanical failure that occurred the very next day.

The representative responds

Matthew Bryant (COBB Support)

Apr 1, 11:18 AM CDT

Hey Rick,

My name is Matt Bryant. I'm the Customer Service Manager at COBB, and also the one that you spoke with yesterday evening.

Below is a screenshot of the failure in the 2/3 gear pull you made and sent over to Aaron (COBB)/Calvin (Kraken) originally when we warrantied the flex fuel module.

As I mentioned on the phone yesterday, the module did indeed fail (indicated in red). You can see the voltage drop down to 0.1. However, due to the programming we've instituted, and the configuration of Calvin's tune, you can see that "Ethanol Final (%)" did not skew to any notable degree. It was consistent at around 72%-73%. Ethanol Final is what the calibration references for tuning purposes. Given that Ethanol Final did not skew, I'm confident in saying that the failure of the module did not contribute to your mechanical failure.

As for the datalogs you sent over:

- datalog 2-16 has no failures. SNS Volts TGV L (V) is rock solid with minimal variation. Referencing Ethanol Final (%), it is also rock solid with minimal variation between 72%-73% measure ethanol.

- datalog 2-17 has no failures. SNS Volts TGV L (V) is rock solid with minimal variation. Referencing Ethanol Final (%), it is also rock solid with minimal variation between 72%-73% measure ethanol.

As for what caused this failure, one can only guess. In my expert opinion, given the nature of this car (race car build, large turbo, built motor internals, nearly maxed fuel system, ~500wHP) I would suspect that something merely failed due to the high stress/heat that's associated with making that kind of power. Things break all the time on a totally stock car, not to mention especially when you're pushing them this hard as you are. Perhaps a spark plug failed, or the fuel pump had a hiccup, or who knows. Modern engines, not to mention heavily modified ones, are incredibly complicated beasts, so it's really tough to say, given the information I have on hand. I wish I could offer more direction, but Kraken and Calvin will be better resources for guiding you through this.

Apologies for not being able to take your call. I wanted to make sure that I had all the information at hand and had ample time to review your logs prior to chatting. If you'd like to speak later this afternoon, feel free to let me know, and I'll be happy to give you a call.

He obviously didn't look very well as the logs and the point of failure so I take the liberty to point it out in my response

From: Richard Wegmann <rickwegmann@me.com>

Date: 4/1/2020

To: COBB Support <support@cobbtuning.com>

Cc: Kraken Motorsports <calvin@dotsontuning.com>,Shawn <shawn@kraken-motorsports.com>

Subject: Re: [COBB Support] Re: Phone Call from: Richard Wegmann

Matthew,

Your observation pertaining to the ethanol content being consistent at around 72% - 73% during the 2 / 3 gear pull is incorrect. We are all in agreement that the actual ethanol content in the car for both logs was in the 72%-73% range. I want to explore the log provided on 2-17 when the engine failure occurred. That engine failure occurred during the cells 2275-2320 when sorted by column A Time (sec)

Cells 2275 ? 2283 shows Ethanol Final (%) 73.3 and Ethanol Raw (%) 73.3-73.6 which is normal when sensor working correctly as confirmed by 2-16 log.

Cell 2284 shows Ethanol Final (%) 73.3 and Ethanol Raw (%) drop to 50.2

Cell 2285 shows Ethanol Final (%) 73.3 and Ethanol Raw (%) drop to 0 when I let off the throttle and change gears

Cells 2286-2302 shows Ethanol Final (%) drop from the 73.3 to a low of 65.2 and Ethanol Raw (%) bounces around from 0 ? 73.3

Why is the ethanol final (%) dropping down to 65.2 when the last good reading was 73.3? Also, I don?t see ignition timing changing to compensate for this drop. This is where I hear the car sounds different and not accelerating as quickly and where I got the engine failure but didn?t know it.

I let off the throttle and then get back into it and then realize I have an issue.

Once I arrive home I send the log over to Calvin and then subsequently over to you guys

He responds

Matthew Bryant (COBB Support)

Apr 1, 6:56 PM CDT

Hey Rick,

Thanks for allowing me time to review your email/logs.

Your concern of Ethanol Final (%) variation, notable between shifts, could be contributed to by the ethanol sensor placement. For the most accurate/consistent performance, we've designed it to be installed within the pressurized system, pre-FPR (fuel pressure regulator). It may be worth confirming that you have it installed in that fashion. If you have it post-FPR, that would indicate why you see the fluctuations when shifting (low pump duty cycle (as you're off throttle), the return line would be nearly empty, the ethanol sensor would calculate erroneous values). Again, the fluctuations in the readout of Ethanol Final are minimal during steady states of throttle.

Even the Ethanol Final swing of 8.1% (65.2% vs. 73.3%) you mentioned would only account for about a small percentage change (single digit) in actual fueling, which is absolutely not enough to cause harm. For that matter, I didn't see any terribly concerning/red-flag lean conditions that would lead to a damaged spark plug or valve.

I still stand by my original statement that I don't believe the module is responsible for the reported engine damage.

Through all of the exchanges Calvin nor Shawn respond so I email them

From: Richard Wegmann <rickwegmann@me.com>Date: 4/1/2020

To: Calvin Dotson <calvin@dotsontuning.com>,Shawn Rizzo <shawn@kraken-motorsports.com>

Subject: Fwd: [COBB Support] Re: Phone Call from: Richard Wegmann

Calvin & Shawn,Are you in agreement with Matthew/Cobb's viewpoint that the 8% swing in ethanol content reading at full boost would not cause the damage that coincidentally occurred at the same time as the sensor failure based on the logs provided?

From: Richard Wegmann <rickwegmann@me.com>Date: 4/1/2020

To: Calvin Dotson <calvin@dotsontuning.com>,Shawn Rizzo <shawn@kraken-motorsports.com>

Subject: Fwd: [COBB Support] Re: Phone Call from: Richard Wegmann

Calvin & Shawn,Are you in agreement with Matthew/Cobb's viewpoint that the 8% swing in ethanol content reading at full boost would not cause the damage that coincidentally occurred at the same time as the sensor failure based on the logs provided?

Alin

Diehard Car Enthusiast!

Wow, not something anyone wants to hear/read (and you experiencing and living it). This is well above my knowledge, so I can only sit back, read, and learn. I know you're relaying the info into text now, but I strongly urge you to get in contact with George and get his opinion and advice (if you haven't already done so yet).

I would love to get his input and send him the logs if he is so willing but he has been so hard to reach the last year or so.

Grinder34

Track Monkey

Wow man, that's terrible to hear. Of course they're being sketchy, they don't want to pay the $$$.

I like that you're getting everything in writing, kudos. From here I would probably try to blow this up a bit more publicly on twitter or the like. A lot of companies seem to respond more favorably when their actions are in the public eye and can tarnish reputation.

I like that you're getting everything in writing, kudos. From here I would probably try to blow this up a bit more publicly on twitter or the like. A lot of companies seem to respond more favorably when their actions are in the public eye and can tarnish reputation.

I did speak with George and he can?t see anything in the log pointing to the sensor failing and suggests looking at the injectors.

The sad part is that is all I wanted was the tuner or the shop to help me figure out the issue. But they all step back and leave me out in the cold.

I really wish George lived closer as I really trust him and value his opinion.

Now I must pull the motor and learn how to fix the issues myself.

Will be a learning curve but the money I will save in the long run will be worth it.

Sent from my iPhone using Tapatalk

The sad part is that is all I wanted was the tuner or the shop to help me figure out the issue. But they all step back and leave me out in the cold.

I really wish George lived closer as I really trust him and value his opinion.

Now I must pull the motor and learn how to fix the issues myself.

Will be a learning curve but the money I will save in the long run will be worth it.

Sent from my iPhone using Tapatalk

Awww man, wtf... Due to the whole statewide lockdown and everything, I haven't been online in a while, so I'm just now seeing this. This is terrible, sorry to hear. :banghead: